PP Woven Ground Covers

Product Details:

- Weight 90 GSM, 100 GSM, 120 GSM, 130 GSM, 150 GSM (Custom as Required)

- Cutting Width Width as per Roll (1m, 2m, 3m, 4m)

- Usage & Applications Weed Control, Landscaping, Greenhouse, Nursery, Horticulture, Vegetable Garden

- Dimension (L*W*H) Custom, Standard Widths with Roll Length 50m, 100m, 200m

- Product Type PP Woven Ground Cover

- Material Polypropylene (PP)

- Finish UV Treated

- Click to View more

PP Woven Ground Covers Product Specifications

- Weed Control, Landscaping, Greenhouse, Nursery, Horticulture, Vegetable Garden

- Polypropylene (PP)

- Custom, Standard Widths with Roll Length 50m, 100m, 200m

- UV Treated

- PP Woven Ground Cover

- 1m, 2m, 3m, 4m Widths (Custom Lengths)

- Width as per Roll (1m, 2m, 3m, 4m)

- 90 GSM, 100 GSM, 120 GSM, 130 GSM, 150 GSM (Custom as Required)

PP Woven Ground Covers Trade Information

- Australia, Eastern Europe, Middle East, Western Europe, Central America, South America, Asia, North America

Product Description

Owing to our broad distribution network and business acumen, we are engaged in manufacturing and exporting the gamut of PP Woven Ground Covers. We always make use of superior quality material to design the entire range. These are largely used to control the growth of weeds. Known for the fine finish and workability, the entire array of PP Woven Ground Covers is available at highly discounted prices.

Features:

- Resistant to UV

- Long lasting

- Chemical resistant

Further Details:

Black ground cover fabric comes in rolls of 300' lengths and is availible in 3', 4', 5', 6', 10', 12', 15' and 17.5' widths. Has green lines running down the length of the fabric 12" apart to make overlapping easier. Great way to keep the weeds out of your way and achieve a nice looking, weed free flower or plant bed.

We can offer PP Woven Ground Covers from 85gsm to 370gsm (2.5 oz to 11 oz). The fabric is made from the latest Sulzer Looms having wide width capabilities. The fabric is treated with UV stabilizers to give longer life.

Technical Specifications

| UV resistant | Yes |

| Weight | 85 - 370 (gsm) |

| Surface | Water permeable / Mildew resistant |

| Fabric Material | Sulzer Looms |

| Black ground cover fabric (length) | 300 (inch) |

| Black ground cover fabric (Width) | 3, 4, 5, 6, 10, 12, 15 , 17.5 (inch) |

Specifications:

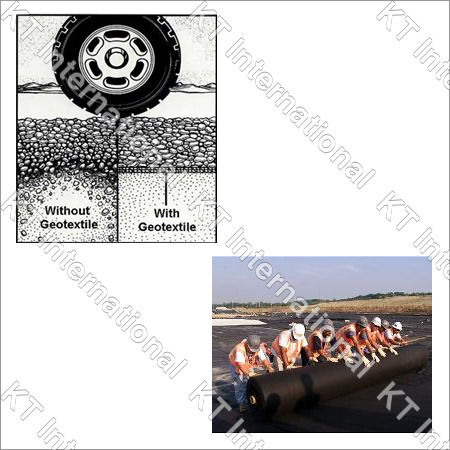

Blocks weeds and reduces erosion

12" marker lines for pot alignment

Water permeable, mildew resistant

Primarily placed on the ground for greenhouse and nursery weed control

May be used under gravel

Versatile Applications in Agriculture and Landscaping

Our PP woven ground covers are ideal for diverse uses, including weed suppression, landscaping projects, greenhouse floors, nursery environments, horticulture, and vegetable gardening. The fabrics strength, alongside its UV treatment, ensures reliable protection and performance both outdoors and indoors, facilitating healthier plant growth and simplified surface management.

Customizable Dimensions and GSM for Every Project

Choose from popular widths1m, 2m, 3m, 4mand customize roll lengths up to 200m or more to precisely fit your space. With varied GSM options from 90 to 150, as well as custom weights, our ground covers can be tailored for light-duty to heavy-duty requirements, providing unmatched flexibility for manufacturers and end-users alike.

FAQs of PP Woven Ground Covers:

Q: How are PP woven ground covers beneficial for weed control?

A: PP woven ground covers effectively suppress weed growth by blocking sunlight and limiting their ability to establish roots, all while allowing water and nutrients to penetrate for healthier crops or landscaping.Q: What material are these ground covers made of and why is it ideal?

A: These ground covers are made from polypropylene (PP), which is chosen for its durability, resistance to moisture, chemicals, and UV rays. This ensures long service life, even under demanding outdoor conditions.Q: Where can I use PP woven ground covers?

A: They are suitable for use in agricultural fields, nurseries, greenhouses, landscaping beds, vegetable gardens, and horticultural settings, helping manage weed control, moisture retention, and ground stabilization.Q: What sizes and thicknesses are available for these covers?

A: You can select from standard widths of 1m, 2m, 3m, and 4m, with custom lengths available upon request. Various thicknesses are offered, ranging from 90 GSM to 150 GSM, and customization is possible for specific needs.Q: How are these ground covers installed?

A: Installation is straightforwardsimply roll out the cover over the prepared soil, trim to your space as needed, and secure with pegs or staples. Overlaps and seams can be managed with tape or by pinning, depending on area size.Q: When is the best time to install PP woven ground covers?

A: The ground covers can be installed at any time of the year, but for best results, apply them before weed growth begins in the planting season or after clearing existing vegetation.Q: What advantages does UV treatment provide for these covers?

A: UV treatment enhances the materials resistance to sunlight, significantly increasing the products lifespan by preventing degradation and brittleness typically caused by extended outdoor exposure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free